Hawk Precision Bullets™

"The World's Premier Custom Bullet Manufacturer"

Hawk is the original developer and producer of "SOFT"™ copper jacketed hunting bullets. We began doing research on hunting bullet design in 1987, and soon learned that even with the additional production difficulties and added cost, the soft jacket had several advantages, and is well worth the extra work.

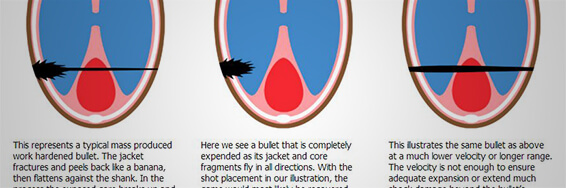

Almost all jacketed bullets currently manufactured use gilding metal or a similar alloy for jacket material. Gilding metal is hard, brittle and work hardens in the forming process even faster than copper. Thus, after the many forming operations needed, we end up with a jacket that is hard and brittle, and fractures on impact, instead of stretching and flowing with the soft lead core. When the soft lead flows beyond the support of the jacket, it either is torn off or thrown off by the centrifugal force of rotation. This is the primary reason it is common to have jacket separation and poor weight retention. However, good weight retention is essential for deep penetration.

Annealing the copper jackets to a "dead-soft"™ condition gives a number of improvements over any other design. They seal the bore and engage the rifling more completely, improving accuracy and eliminating gas blow-by. Barrel friction is about half that of a hard jacket bullet, thus fouling is reduced. All of the forgoing improves accuracy.

Our "soft"™ jackets stay together, even with 3 diameters of expansion. They stretch and flow to support the mushrooming lead core, keeping the bullet intact even in extreme deformation or expansion.

We would quickly agree that there are designs that perform well in particular cases, We have not discovered the universal magic answer to all situations. However, our design has demonstrated a real improvement in performance on game and with its accuracy, at a reasonable cost.

The "soft"™ jacket doesn't do it all. Uniformity and quality are crucial. We draw our own tubing, make our own jackets, and extrude our own lead cores to insure complete control and the highest quality. Virtually, all other bullets are made with a much harder alloyed lead core that contains tin and/or antimony. The Hawk Precision bullet uses a pure lead core which is softer and ballistically superior. We are able to hold our weight control several times closer than the commonly used industry standard. Every run, even 400 & 500 grain bullets are held within 1/2 grain. We don’t sort and sell different grades. We actually make every production run to this high standard, and then check every bullet and mark the variation on each box before shipping.

Hawk Precision Bullets, recovered from moose.

.338 x 275gr x .035 RT

Left: .875 dia. x 87% weight retention

Right: 1.05 dia. x 90% weight retention

HOW ARE HAWK BULLETS DIFFERENT?

ACCURACY - Superior accuracy is our number one objective, and we deliver it in all calibers. We believe we produce the most accurate premium hunting bullets available anywhere (confirmed by independent tests).

PERFORMANCE ON GAME - Our "soft"™ jacket bullets expand to 2-3 diameters, thus producing larger wound channels and more one-shot hunts, yet they retain 80-95% of their original weight to punch deep into their target.

KIND TO YOUR BORE - Hawk bullets are easy on old soft iron barrels. They obturate easily to completely seal the bore and eliminate gas blow-by.

Hawk bullets usually shoot very well in worn or pitted bores.

LARGEST SELECTION - We produce the world’s most complete line of hunting bullets, including most European and obsolete calibers.

We offer bullets for the individuals particular need; bullets suited for all velocity levels and different types of game with 5 different jacket thicknesses available. You will also find bullets in most calibers for lower "black powder" velocities or single shot pistols, etc.

Selecting a Bullet

Bullet Selection

849 Hawks Bridge Road

Salem, NJ 08079 USA

Tel: (856) 299-2800

Fax: (856) 299-2700

Email: info@hawkbullets.com

© Hawk Incorporated 1994-2021. All Rights Reserved.